Last year, China’s foreign trade exports to achieve a surge, while driving the development of many industries, such as fitness equipment, steel furniture, kitchen bathroom, etc., the growth of orders to make laser tube cutting machine can be used more space; With the promotion of Made in China 2025, metal tube cutting machine technology is also facing changes and opportunities. Under the existing background, the laser cutting machine has been transformed and upgraded on the original technology. With the development of industrial technology, laser cutting has been applied to all walks of life. Mechanization and automation will be the main melody of the development of enterprises in the future.

Steel pipes are widely used in various industries. Generally, the standard length of steel pipes is 6 meters. However, because the application scenarios do not need to meet different processing requirements, the commonly used metal pipe processing is cutting, bending, welding, Punch. Among them, cutting and punching take up the most diverse processes. The laser pipe cutting machine has allowed many steel pipe companies to usher in a change on the basis of the original sawing. The traditional saw blade cutting is actually very inefficient, and it is easy to make the pipe during the cutting process. Extrusion and saw blades are also expensive accessories.

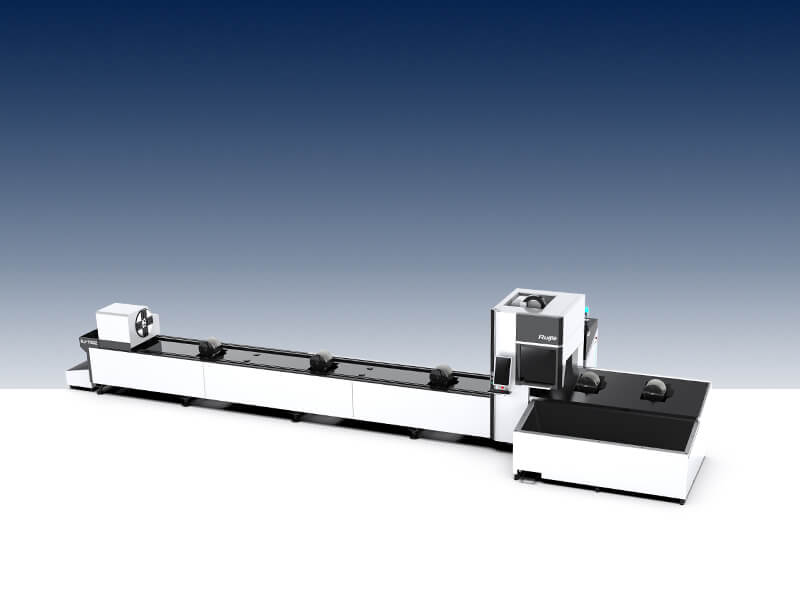

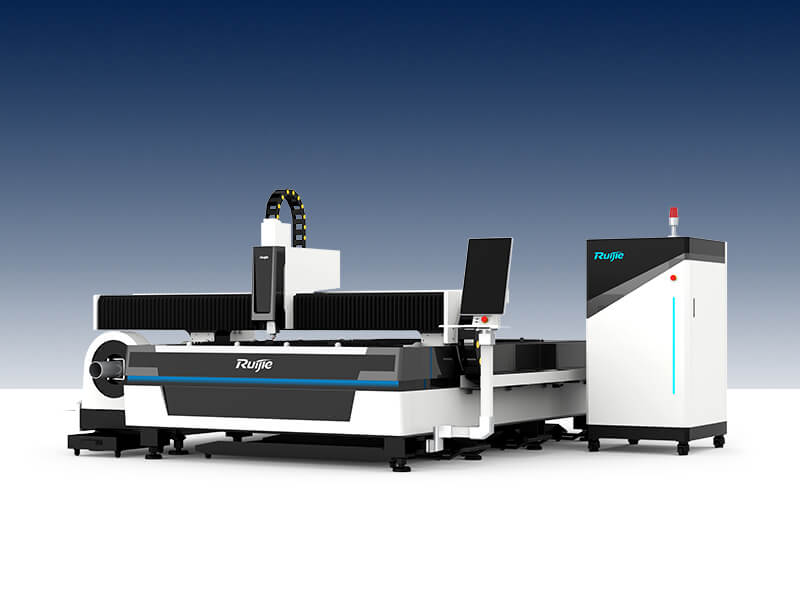

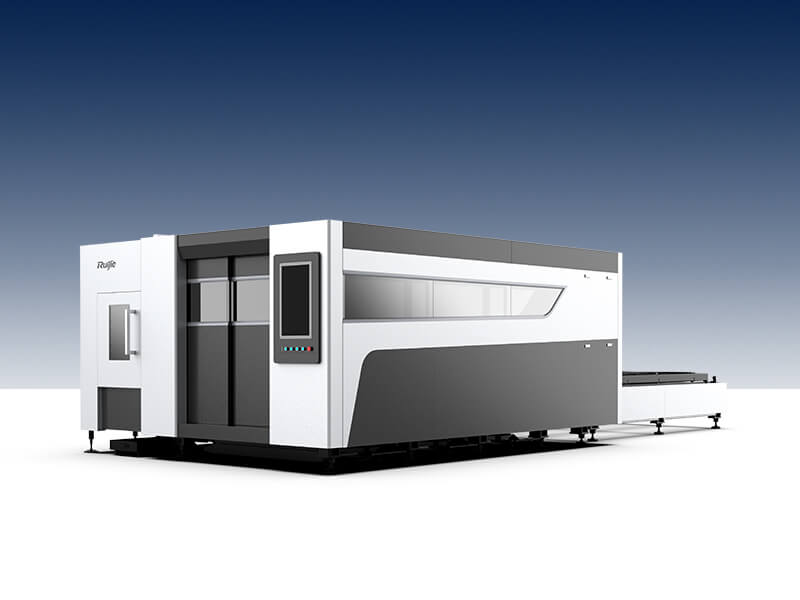

Laser technology has developed rapidly in recent years and has been gradually applied in many industries. Laser cutting has gradually developed from a single plane plate cutting to metal composite materials, such as three-dimensional groove cutting, special-shaped pipe cutting. The advent of professional laser pipe cutting machine has greatly improved the production efficiency of metal composite pipe. The basic cutting concept of professional laser cutting machine is no different from the plane plate laser cutting machine. The laser cutting machine mainly cuts standard and non-standard parts, standard parts such as round tubes, square tubes, oval tubes, non-standard parts such as Angle steel, channel steel, I steel, composite profiles and so on. Compared with traditional processing technology,metal tube laser cutting machine has the following advantages:

(1) High cutting precision, the pipe accuracy can be stable at ±0.03mm;

(2) The cut surface is smooth, flat and free of burrs, with small cut seams and less loss of raw materials;

(3) Non-contact cutting, laser cutting is local thermal processing cutting, the heat-affected area is small, and the cut product is basically free of deformation;

(4) High cutting efficiency, can be equipped with automatic feeding function, capable of batch cutting for a long time;

(5) The operating system interface is simple and clear, the operation process is simple, only need to import design drawings, can fast cutting and processing, processing process can be real-time monitoring, safe and stable processing efficiency is high

(6) It can carry out high efficiency production and manufacturing in large quantities, high precision of cutting pipe, no deformation of material, no need for secondary polishing and other processing, saving cost;

To sum up, a professional laser cutting machine can complete the opening, drilling, sawing and other processes, the final product does not need to polish. One equipment can complete the work of four traditional equipment, and only need one fifth of the time of the traditional process, can complete the same or even better finished products. Professional laser pipe cutting machine has successfully changed the current pipe processing market. At present, laser tube cutting machine has been widely used in sheet metal processing companies, kitchen appliances, lighting equipment, cars, medical equipment, hardware, fitness equipment and other industries. If you want to know more about tube laser cutting machine cost, please contact Ruijie.